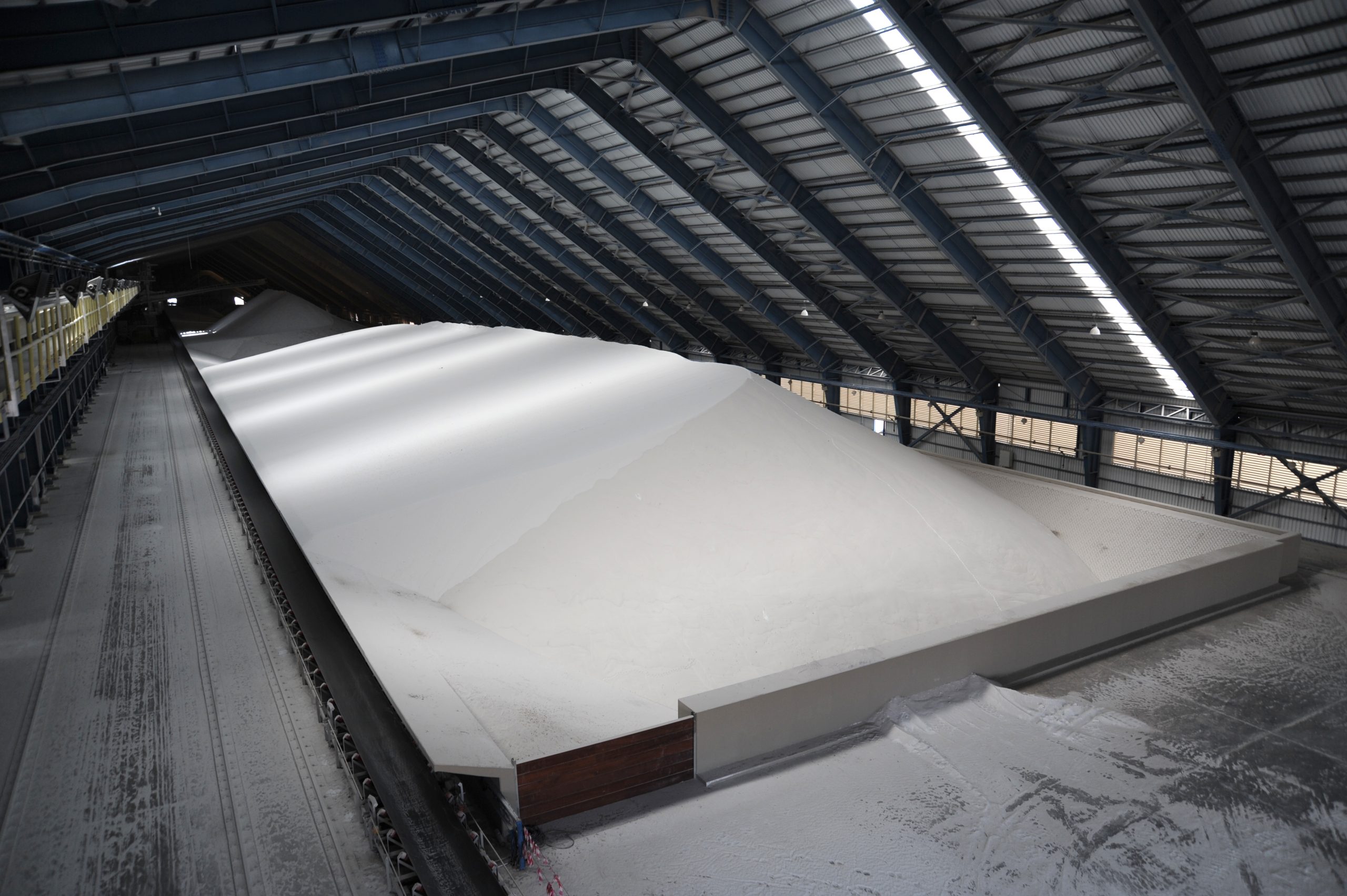

Aqaba Project

Aqaba Project services included mechanical redesign, full system control design, and commissioning with fully automated stacking and reclaiming equipment.

Stacking System- 6 plant conveyors, 900 TPH

- 7 feeder conveyors, 4 truck dump hoppers

- 2 diverters, 3 Silo, 3 dust systems

- 3 mobile stackers w/ 2 conveyors and hydraulic boom control

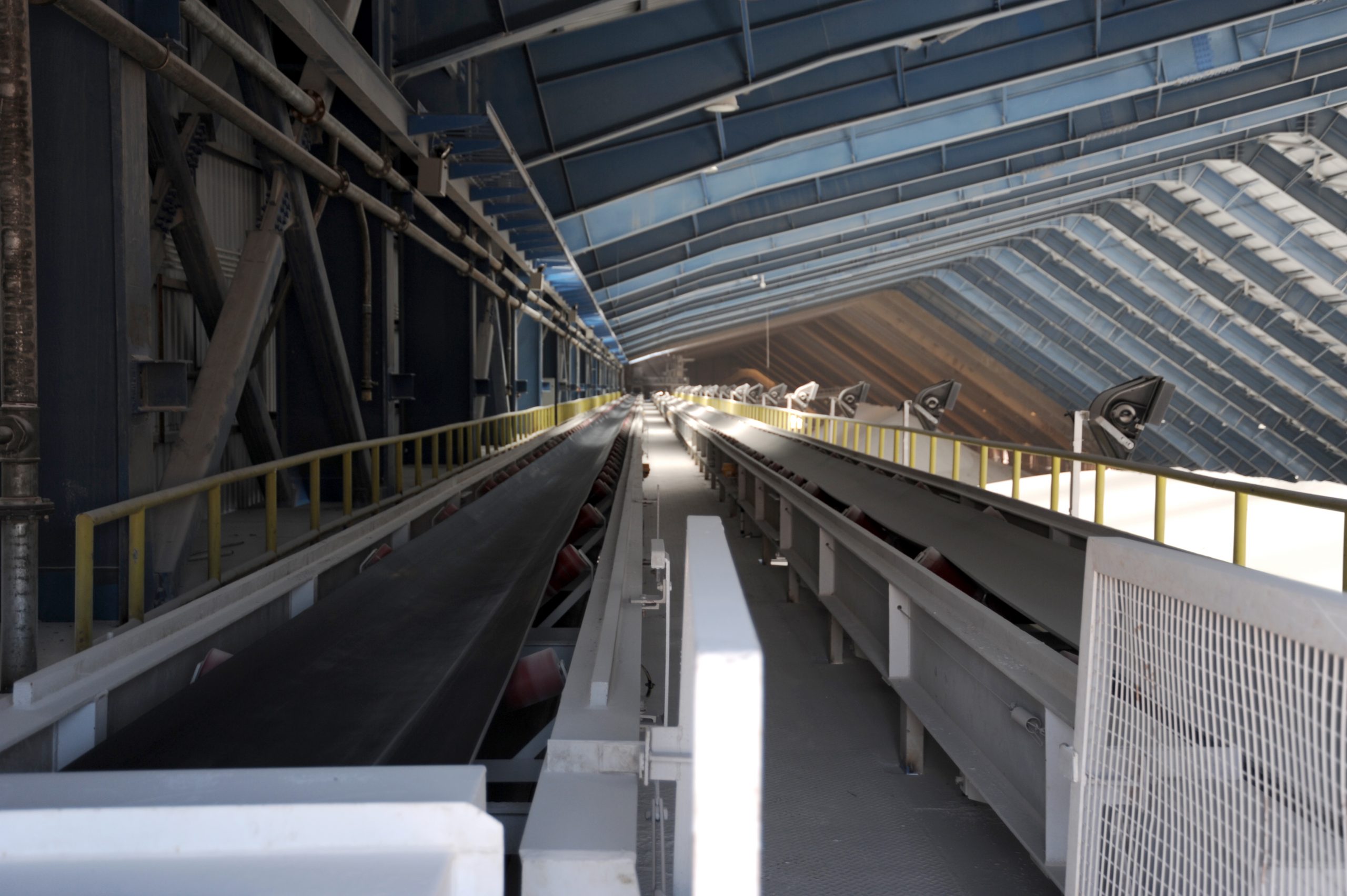

- 11 plant conveyors, 1000 TPH

- 8 diverters, 1 screen, 9 dust systems

- 7 remote plant conveyors w/ 4 diverters, 2 shiploaders

- 2 mobile reclaimers w/ 3 chains and 3 2-speed winch motors

- Direct start with fluid coupling

- Resistor step start (Auto-stepping) MV motor

- Variable speed hydraulic feeder motors

- DC Drives (ABB DCS800) Stackers and Reclaimers

- Electro-mechanical brakes

- 3 ABB DCS Processor (AC800M) Stacker Control w/ hot backup

- 2 ABB DCS Processor (AC800M) Reclaimer Control w/ hot backup

- 3 ABB DCS Processor (AC800M) Plant Control w/ hot backup

- 2 ABB DCS Servers

- 3 SCADA Operator station, 1 engineering station, 2 control rooms

- 3 Operator interface (ABB Process Panel)

- Multiple networks (Ethernet, ProfiBus, ModuleBus)

- Fault tolerant fiber optic network (Ethernet, ProfiBus)