Forensic Analysis

In the forensic failure analysis service, it is possible to identify the root cause of failures that have occurred in conveyor systems. CDI uses a variety of instruments, including many of our own design, and a DAQ system and software of our own making, to measure a variety of performance parameters during conveyor start, continuous operation, and stop. Some of these parameters are:

- Belt speed

- Torque applied

- Tensioner position

- Lateral displacement

- Brake response time

CDI also uses BELTSTAT and BELTFLEX as forensic analysis tools to simulate conveyors developed by others, to audit their design, or in existing conveyor systems to duplicate and troubleshoot operational problems. This type of analysis can substantially reduce the amount of downtime involved in identifying and replacing a poorly designed component or poor maintenance and control systems.

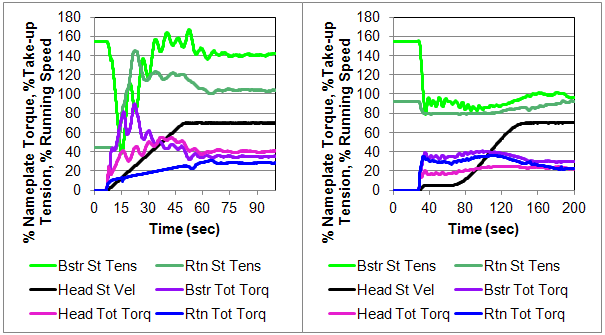

Collected data on conveyor performance is analyzed and behavior is simulated with BELTFLEX. Based on our measurements and simulations, CDI will recommend changes to conveyor control systems, or recommend replacement of defective or poorly designed components.

The charts below show a case study in which the CDI forensic analysis of the transport system, CDI eliminated transmission control instabilities causing excessive system downtime due to accelerated belt wear, motors and the tensioner system of this particular belt.